Automated electrostatic coating

NACL anodizing under-coat

As an under-coat treatment for painting of aluminum building materials, cromate coating or sulfric acid anodic oxidation film are wldely used. However, cromate coating has a problem of peeling the coat due to a non-uniformed film and also has a problem of waste water pollution. Therefore we, NACL recommend a sulfuric acid anodic oxidation film as an under-coat for painting.

-

- Ecology

- Any waste water pollution or any environmental pollution does not occur because of non-use of chrome chemicals.

-

- High adhesion

- Because of the excellent adhesion, any film peeling does not occur.

-

- Excellent hardness and wear resistance

- Excellent hardness and wear resistance can be obtained.

-

- Coloring is available

- Because of an anodizing under-coat, it is possible to color.

Painting specification by NACL Anodizing coating / Painting specification by Chromate coating

| Structure of the coating film (Specification sample : Hot temperature fluorine resin painting) |

||

|---|---|---|

| NACL Anodizing under-coat process |

|

(1)

Anodizing under-coat can improve the film adhesion by itself. And corrosion resistance of the anodizing film is excellent compared to that of the chromate coating. |

| (2)

In case of the coating thickness of anodizing film 6µm + fluorine painting film 25µm,

|

||

| (3)

Therefore the total film thickness is comprising of 100% flourine resin paints according to the specification requirement. |

||

| Conventional Chromate coating process |

|

(1)

Conventional under-coat needs to use the chromate which includes a pollutant of Cr6+. Therefore it leads to a pollution problem. |

| (2)

Primer coating(an undercoat) is necessary as the joint between chromate film and fluoric resin. |

||

| (3)

Epoxy resin is used as the main material of primer, but epoxy base is easily degraded by the ultraviolet rays. |

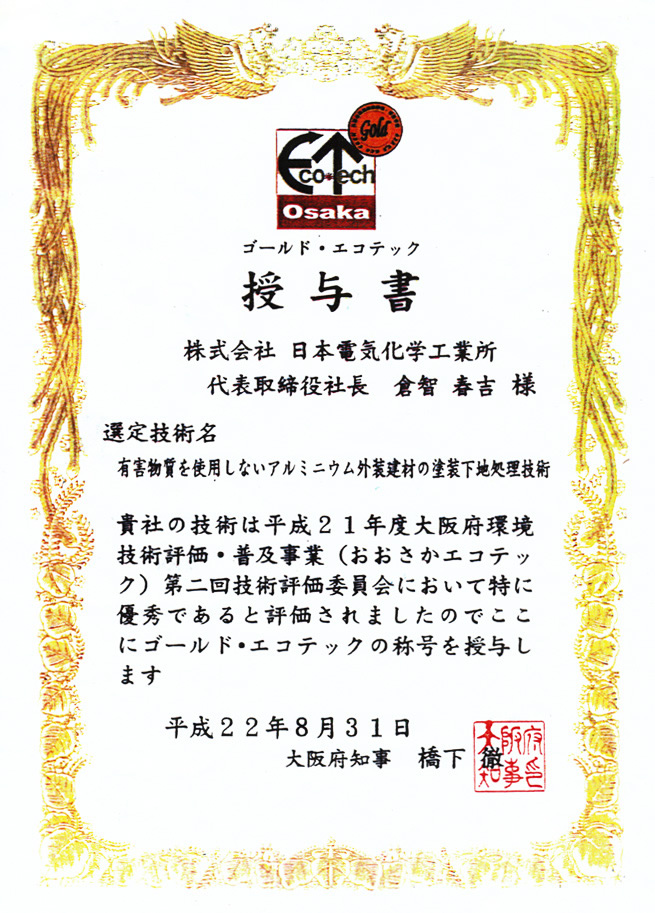

Gold EcoTech Certificate

Gold EcoTech Certificate

Dear Mr. Harukichi Kurachi

President of Nihon Anodizing Co. Ltd.

- Selected technology:

- Surface pretreatment technology prior to painting on aluminum building exterior materials without using any harmful substances.

Since your technology was highly recognized by 2nd technology assessment committee of Osaka EcoTech 2009, we bestow on you a title of Gold EcoTech.

August 31, 2010

Toru Hashimoto

Osaka Governor

- Process outline